Aircraft Prop Balancer - Smooth running machines take longer and operate with operator fatigue. The cost of aircraft engines makes it even more important to maintain them to extend engine life and performance.

An airplane propeller is basically a giant flywheel attached directly to the output shaft of most single-piston airplanes. With this "direct drive" approach, the engine and propeller are essentially one integrated unit. If the rack is out of balance, then the engine is out of balance.

Aircraft Prop Balancer

The prop builder adjusts prop balance statically, meaning the prop is balanced, but only with itself. Engine manufacturers also standardize engines to varying degrees of refinement.

Carbon Fiber Magnetic Propeller Balancer Prop Essential For Quadcopter Fpv Helicopter Airplane

Why is a balanced pole connected to a balanced motor not actually balanced? Each has slightly different balance points. It is this difference that creates the vibration.

Dynamic balance of medication. Dynamic balancing is achieved by adding a very small amount of weight in the form of a tactically mounted washer to the support mounting flange.

A special sensor is attached to the prop blade and a computer program detects the rotation of the imbalance as the prop rotates, indicating where to place the counterweights against the main prop.

The proof is not only in the data, but also in the feel of the aircraft. Other experienced pilots were amazed at how smoothly the engine ran.

Dynamic Propeller Balancing

A quality dynamic balance is $200-350, depending on the store price and the part of the country. Many stores charge a fixed fee for service. Worth every penny. A propeller naturally vibrates. Some vibration is inevitable, but an unbalanced propeller can cause problems for both the aircraft and its pilot. Small adjustments to the propeller balance can dramatically reduce vibration throughout the aircraft. Double M Aviation provides detailed and reliable propeller alignment.

The lower the aircraft vibration, the longer the aircraft and its components will last. Additionally, excessive vibration can contribute to pilot fatigue, making the flight experience uncomfortable at best and dangerous at worst. Excessive vibration can affect any part of the aircraft. Loose rivets or cracks in the hull may indicate a problem with propeller vibration. In addition, the propeller must be balanced every time it is reinstalled on the aircraft after overhaul or repair. These are situations where the screw may be out of balance and would benefit from inspection and adjustment.

A pilot may not always feel or hear the vibrations, so the vibrations may increase without their knowledge. Vibration can be from a statically unbalanced propeller, where one blade weighs more than the other, or from a dynamically unbalanced propeller, where something else in the aircraft affects the performance of the propeller. Let Double M Aviation take the guesswork out of diagnosing a propeller failure.

Mike Naab and Mike Bowen worked on all the planes I had. They recently transformed my B-55 Baron from a 1970's round dial aircraft into a state of the art 21st century aircraft. This is possible due to their state-of-the-art facility at KLAL and extensive network of related services. Double M can and will provide "no excuses" solutions. After being a customer of Aircraft Engineering for many years, I could never imagine having a better experience. Double M far exceeded my experience!

Cessna Flyer Association

Contact us to discuss our commitment to improving aircraft safety and reliability through quality maintenance. Need to make a reservation? We are available by phone at 863-940-3450 or by email at info@ We can't wait to help you reach the sky! Propeller imbalance, which is the source of aircraft vibration, can be static or dynamic. Static propeller imbalance occurs when the center of gravity (CG) of the propeller does not coincide with the axis of rotation. Dynamic unbalance occurs when the CGs of similar propeller elements, such as blades or counterweights, are not in the same plane of rotation. Dynamic imbalance resulting from improper distribution, since the length of the propeller assembly along the engine crankshaft is short compared to its diameter, and the blades are attached to the hub so that they lie in a plane perpendicular to the axis of motion. if the road resistance requirements are met, the mass is small. Another type of propeller imbalance, aerodynamic imbalance, occurs when the force (or drag) on the blades is unequal. This type of imbalance can be largely eliminated by checking the blade contour and blade angle setting.

The blade test stand has two hardened steel flanges that allow the assembled propeller to rotate freely between them. [Figure 1] The knife edge test stand should be located in a room or area free of any air movement and preferably away from any source of strong vibration.

If the propeller is properly statically balanced, it will stay put no matter what. Check the balance of two-blade propellers: first with the blades in the vertical position, then with the blades in the horizontal position. Repeat the vertical position check by reversing the blade positions; i.e. the blade checked in the low position is placed in the high position.

When checking the static balance of the propeller, all blades should be at the same angle of the blade. Before performing the balance check, ensure that each blade is set at the same blade angle.

Video: Project Update And Dynamic Propeller Balancing

Unless otherwise specified by the manufacturer, an acceptable balance check requires that the propeller assembly not tend to rotate in any of the positions previously described. If the propeller is perfectly balanced in all the described positions, it must also be perfectly balanced in all intermediate positions. If necessary, check the balance in the intermediate positions to confirm the verification in the originally described positions. [Figure 3]

When the propeller assembly is checked for static balance and the assembly has a certain tendency to rotate, certain adjustments are allowed to correct the imbalance.

Where to add or remove weight to correct propeller imbalance is determined by the propeller manufacturer. The method and point of application of unbalance correction should be checked for compliance with existing drawings.

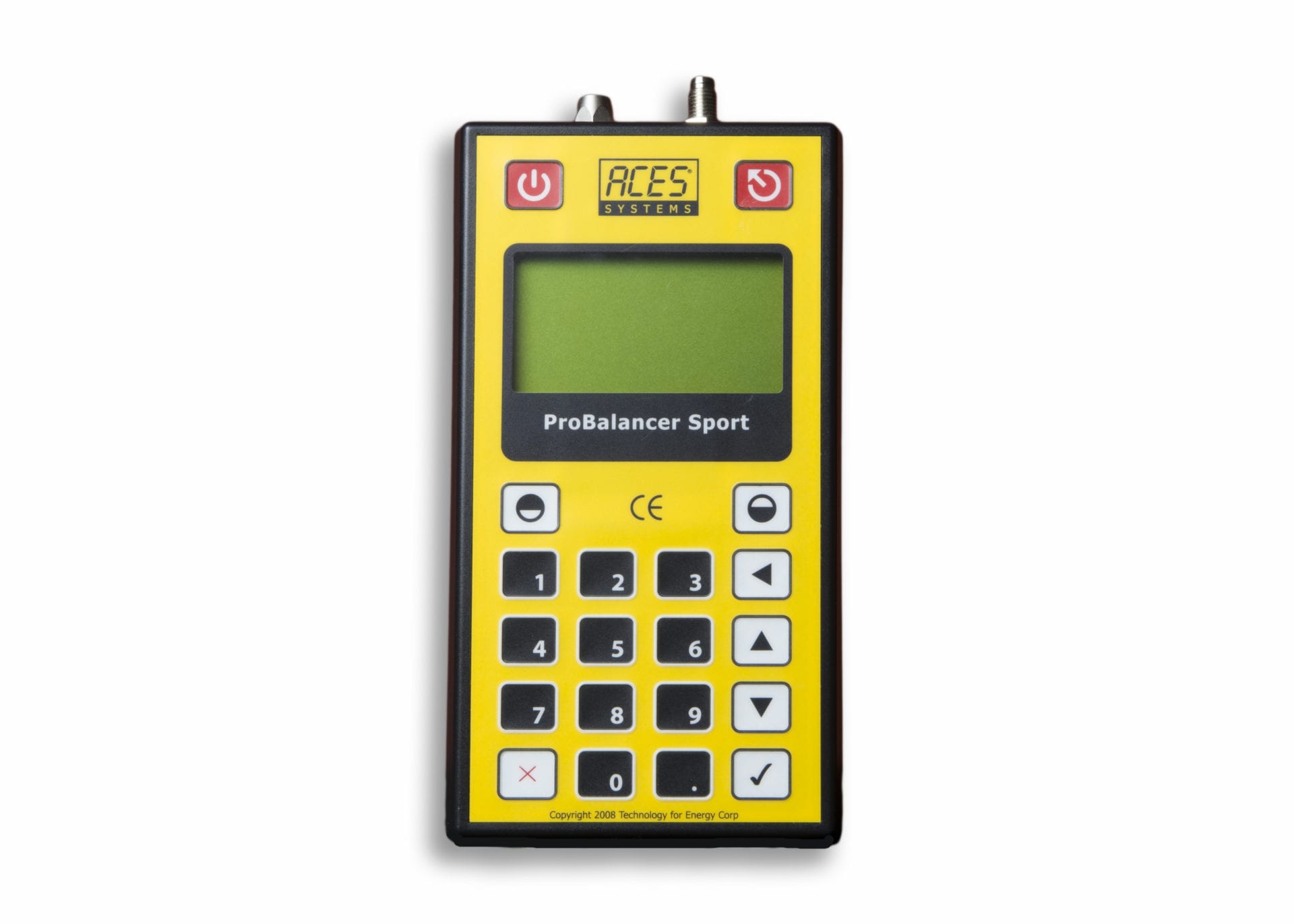

Propellers can also be dynamically balanced (spin balance) using an analyzer kit to reduce propeller and rotor vibration levels. Some aircraft have the system hard-wired into the aircraft, while other aircraft require sensors and cables to be installed before balancing can be performed. Strong alignment can provide significant reductions in transmitted vibration and cabin noise, as well as reduce excessive damage to other aircraft and engine components. Dynamic imbalance can be caused by mass imbalance or any aerodynamic imbalance. Dynamic balancing only improves vibrations caused by mass imbalances in the external rotating components of the drive system. If the engine or aircraft is in poor mechanical condition, balancing will not reduce vibration levels. Defective, worn or loose parts make balancing impossible. Several manufacturers make dynamic propeller alignment equipment and their use of the equipment may vary. A typical dynamic balancing system consists of a vibration sensor attached to the engine close to the propeller and an analyzer unit that calculates the weight and position of the balancing weights.

Lord Looks To Extend Emea Presence

Turn the airplane directly into the wind (20 knots maximum) and set the wheels. When installing the analysis equipment, run the engine at low revs; the dynamic analyzer calculates the required balancing weight at each blade position. After installing the balance weights, restart the engine to check if the vibration levels are reduced. This process may need to be repeated several times before satisfactory results are achieved.

An example dynamic balancing procedure is described here, but always refer to the airplane and propeller instructions when performing any balancing procedure. Dynamic balance is achieved by using tools to accurately measure the size and location of dynamic imbalance. The number of installed weights should not exceed the limit specified by the propeller manufacturer. In addition to the propeller specifications, follow the dynamic balance equipment manufacturer's instructions for dynamic balancing.

Most equipment uses an optical pickup that senses the reflective strip to read RPM. It also has a motor-mounted accelerometer that senses vibration in inches per second (ips).

Visually inspect the propeller assembly prior to dynamic balancing. The first run of a new or overhauled propeller assembly may leave a small amount of oil on the blades and on the inner surface of the centrifuge dome. Use Stoddard solvent (or equivalent) to completely degrease the blades or the inside of the centrifuge dome. Visually inspect each set of propeller blades for evidence of oil leakage. Visually inspect the inside of the centrifuge dome for oil leaks. If there is no evidence of oil leakage, lubricate the propeller according to the maintenance manual. If an oil leak is evident, locate and repair the leak before relubricating and dynamically balancing the propeller. Before dynamic weighing, record the number and location of all scale weights. Static equilibrium is achieved

Bi Plane Balancer

Aircraft prop, dynavibe prop balancer, dubro tru spin prop balancer, aircraft wheel balancer, magnetic prop balancer, dynamic prop balancer, tru spin prop balancer, rc boat prop balancer, rc prop balancer, dubro prop balancer, aircraft tire balancer, prop balancer

0 Comments